Vacuum Heat Treating

Gas Nitriding of Titanium

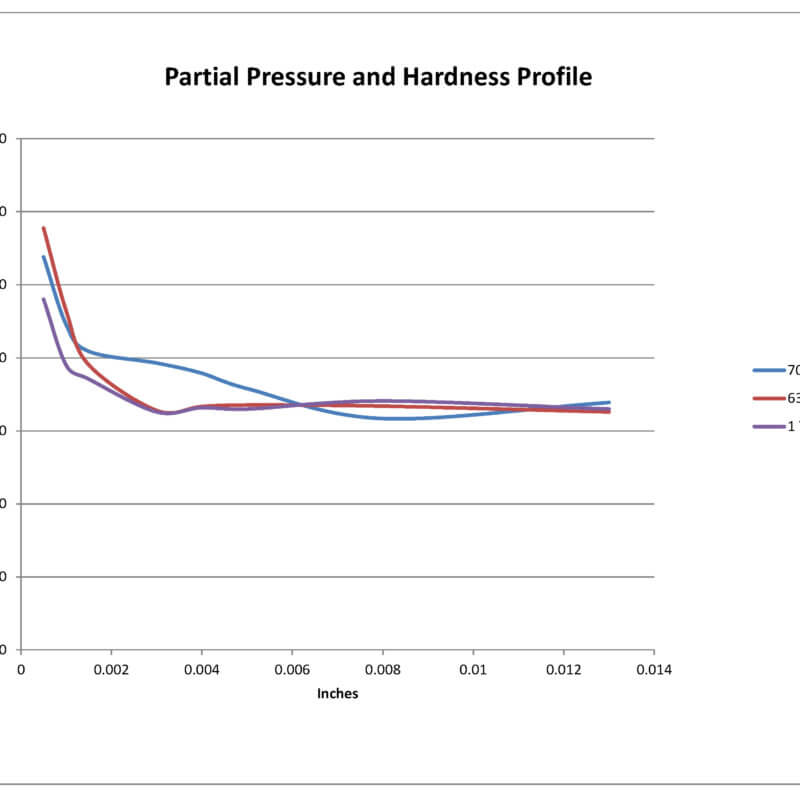

This preliminary study revealed that the partial pressure of nitrogen when gas nitriding Ti-6Al-4V in a vacuum furnace can have a significant effect on the nitrided case characteristics.

Dew Point Versus Oxygen Content in Vacuum Processing Part 2

Since the majority of commercial and captive heat treat facilities do not typically operate under controlled environments, the temperature and humidity swings can often be drastic.

Dew Point Versus Oxygen Content In Vacuum Processing

It is well known that accurate measurement of any heat treating atmosphere can have a significant effect on the quality and process yield of heat treated components. Traditionally, dew point analysis has always been the bellwether in determining our heat treating atmospheric conditions.

Minimizing Alpha Case During Vacuum Heat Treating Titanium

Understanding detrimental alpha case formation during heat treatment of titanium parts is increasingly important as titanium use in aerospace and medical applications continues to grow.

Using Vacuum Furnaces to Heat Treat 3D-Printed Parts

Vacuum heat treating is a crucial step in the additive manufacturing process cycle to meet required part quality specifications.

Minimizing Alpha Case During Vacuum Heat Treating Titanium

A presentation by Solar's Don Jordan given at the ASM's Heat Treat 2015 trade show about reducing alpha case on titanium parts when heat treating in a vacuum furnace.

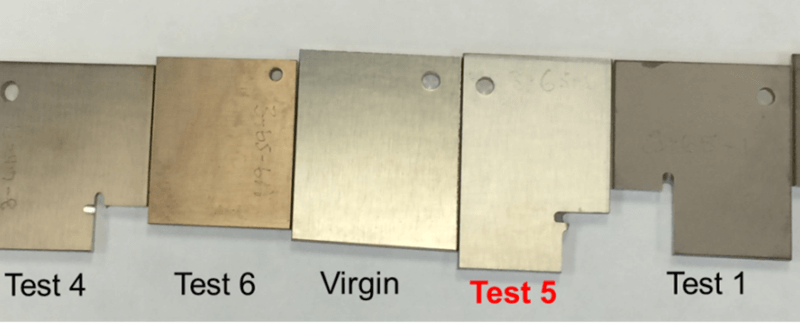

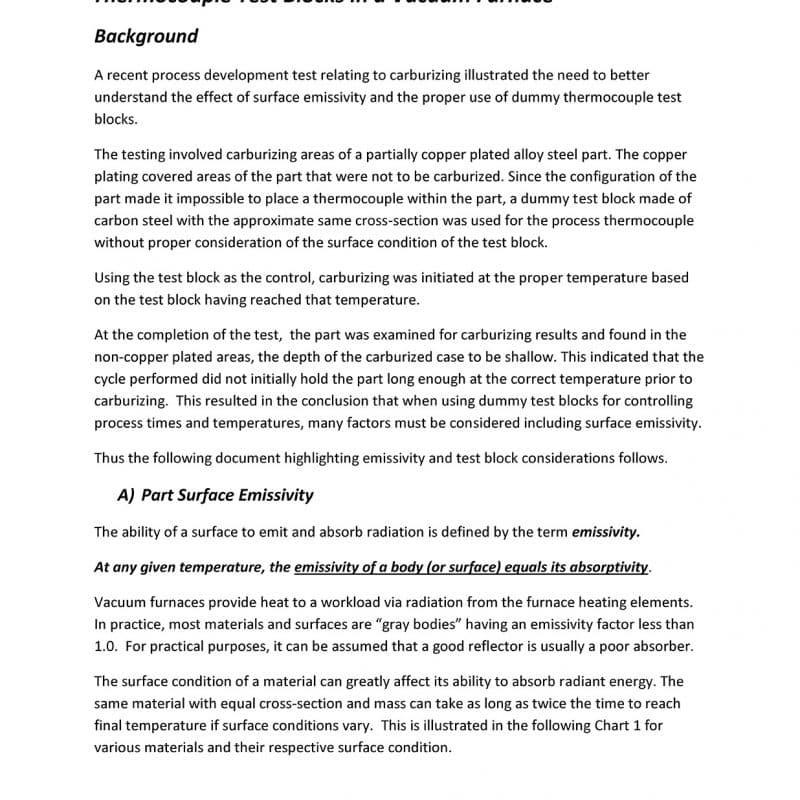

Understanding Emissivity and Thermocouple Test Blocks

A recent process development test relating to carburizing illustrated the need to better understand the effect of surface emissivity and the proper use of dummy thermocouple test blocks. The testing involved carburizing areas of a partially copper plated alloy steel part. The copper plating covered areas of the part that were not to be carburized. Since the configuration of the part made it impossible to place a thermocouple within the part, a dummy test block made of carbon steel with the approximate same cross-section was used for the process thermocouple without proper consideration of the surface condition of the test block. Using the test block as the control, carburizing was initiated at the proper temperature based on the test block having reached that temperature. At the completion of the test, the part was examined for carburizing results and found in the non-copper plated areas, the depth of the carburized case to be shallow. This indicated that the cycle performed did not initially hold the part long enough at the correct temperature prior to carburizing. This resulted in the conclusion that when using dummy test blocks for controlling process times and temperatures, many factors must be considered including surface emissivity.

What the Medical Industry Can Learn from the Aerospace Industry in Heat Treating Components

Heat treatment standards are stricter in the aerospace industry than in the medical industry where lives are on the line. This doesn’t make sense and something is being done about it. Recently, I was asked to give a vacuum heat treating presentation to a group of design engineers at a large medical device company. The lead engineer asked if I would help educate his team on this subject primarily because they had just experienced a major failure caused by improper heat treatment. After learning more about the failure, it became evident that the medical device engineers in that room could learn a great deal from the aerospace industry, especially regarding knowledge of aerospace materials and secondary aerospace processes. It also became apparent that an industry-managed oversight program addressing the technical competency required in special processing was necessary in order for medical device companies to improve design and manufacturer of future medical devices.

True Cost of Becoming an Aerospace Accredited Heat Treating Company

A presentation by Solar's Bob Hill given at the FNA 2014 trade show about the True Cost of Becoming an Aerospace Accredited Heat Treater. Nadcap and AS9100 registered.

Airplanes Don’t Fly Without Heat Treating

Heat treating is the unsung hero of the commercial and military aviation industries. Much like the support staff behind any good play or movie, and the mom behind the Olympic athlete, heat treating of critical aerospace parts is relegated to the background, to the fine print of the credits…if at all. But if it weren’t for heat treating, planes wouldn’t fly, ships wouldn’t sail, submarines wouldn’t dive, and cars wouldn’t drive. This article introduces you to the technical world of vacuum heat treating and why vacuum thermal processing is vital to the aerospace and defense industries. First, let’s nail down what we mean by “heat treating.” In simple terms, heat treating is cooking metal much like you would cook food – with a predetermined recipe and desired outcome in mind. Metal is placed into an oven, or more accurately a furnace (ovens typically don’t handle temperatures over 1,000°F), and precisely held at a specified temperature for a pre-determined period of time. The metal is then cooled either slowly or quickly depending on what properties are desired. Thermal processing can make the metal harder, softer, stronger, more flexible, more rigid, more wear resistant, chemically altered, or a host of other desirable properties.