Vacuum Sintering Services

Vacuum Sintering Services

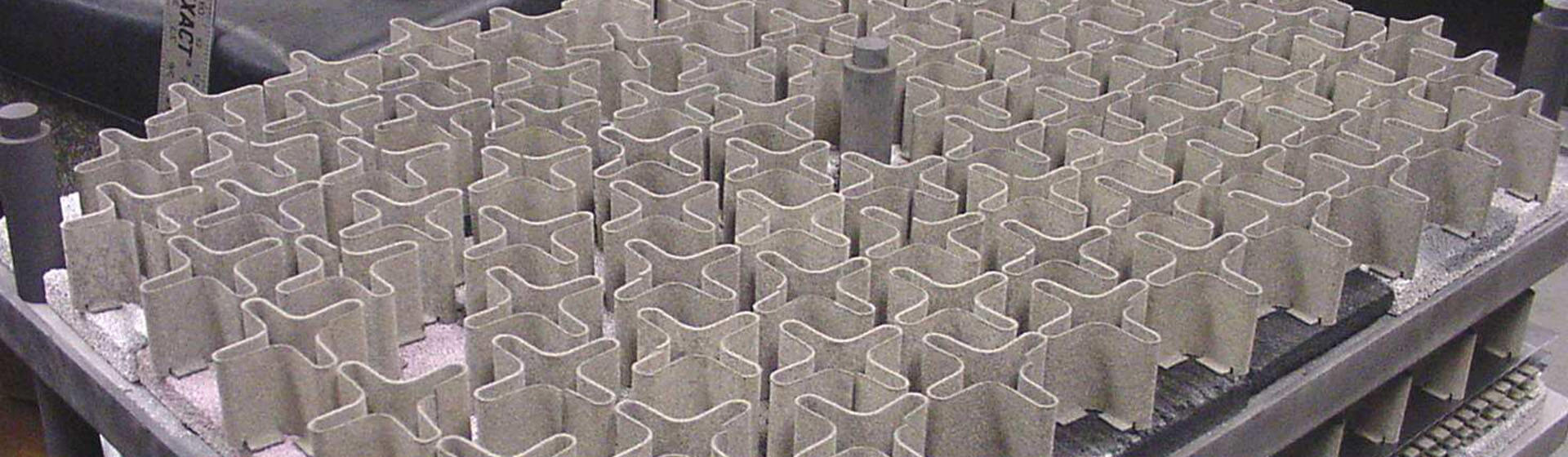

Precise Temperature Controls, Bright Results

Vacuum sintering is the process of forming a single mass from multiple components, typically powder, by heat and/or pressure without melting the base materials to the point of liquefaction. It is imperative that the sintering atmosphere be clean enough to prevent oxidation, otherwise the surfaces of the powder are not clean enough to bond to each other. This makes vacuum the ideal atmosphere for sintering. As in annealing, brazing, and stress relieving, vacuum sintering may assure the parts remain bright at the outset. Precise temperature control is paramount in sintering and most of the time the temperature is higher than typical heat treating processes.

Unique Capabilities

- Large furnace capacity (up to 48 feet)

- Vacuum levels to 1×10-5 torr

- Hydrogen partial pressure available

- On-site metallurgical test lab

- Production or one-off jobs

- Cryogenic stabilization processing

- ITAR Registered

Materials Processed

- 17-4PH / 15-5PH

- 300 Series Stainless Steels

- Alloy 718

- Carbon Steel

- High Strength Steel

- And many others!