Self Cleaning Vacuum Furnace

Before any vacuum heat treatment can begin, components must be thoroughly cleaned to remove both organic and inorganic contaminants. Standard cleaning methods—such as solvent immersion, drying, and vapor degreasing—are essential for eliminating residues that might volatilize during processing. Left unchecked, these contaminants can redeposit inside the vacuum furnace, degrade part quality, and even damage the hot zone or cold wall.

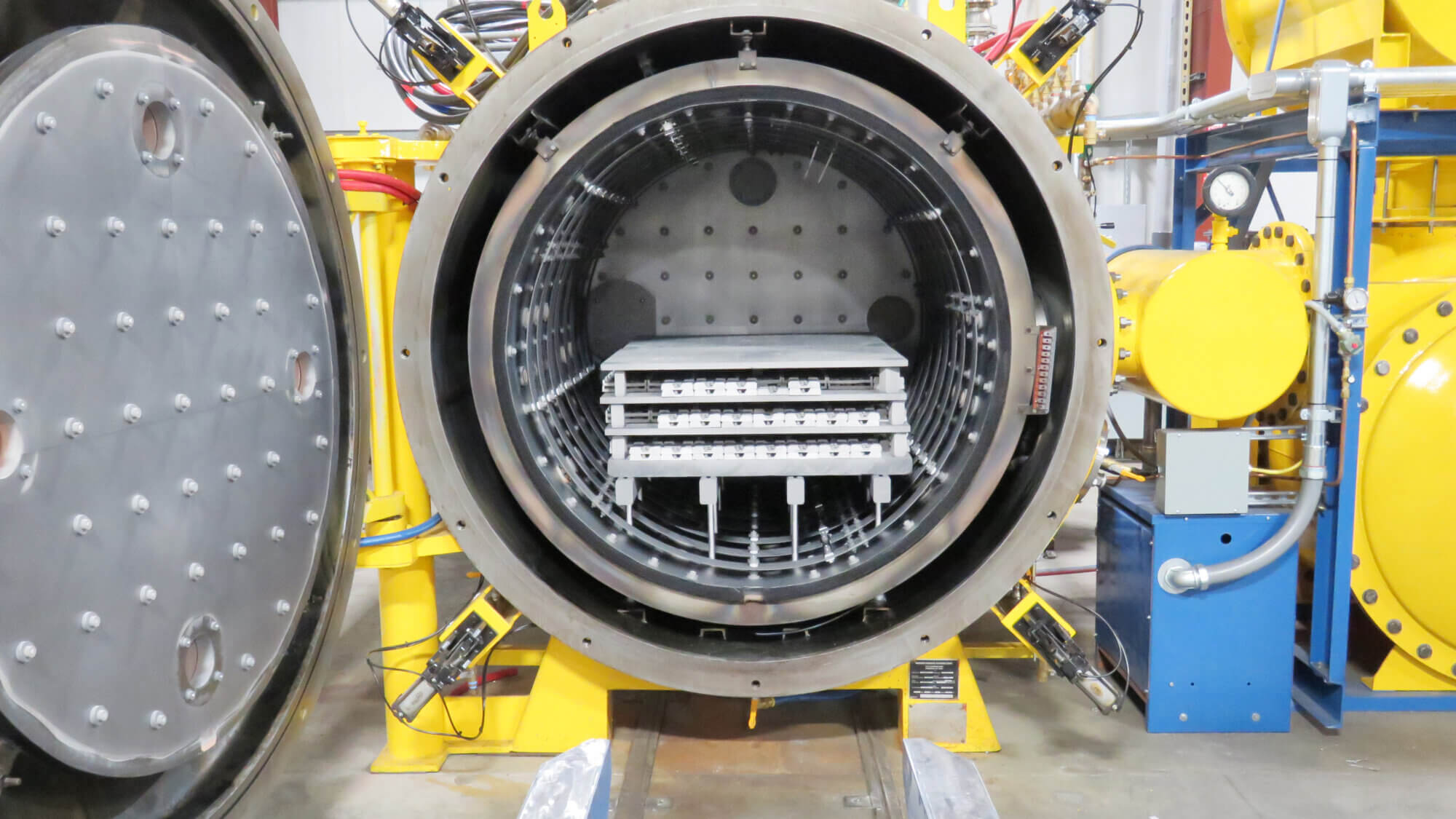

For years, achieving consistent cleanliness in vacuum heat treating has been a persistent industry challenge, often requiring significant labor, expensive chemicals, and the use of stainless steel or titanium foil. Solar Atmospheres’ innovative dual-pump vacuum cleaning system changes that dynamic. Integrated directly into a standard heat treatment cycle, this technology establishes a new benchmark for cleanliness and process efficiency.

This “self-cleaning furnace” approach not only produces exceptionally bright, clean parts—it also enhances safety, minimizes environmental impact, and lowers operating costs. In a time when precision, cleanliness, and sustainability matter more than ever, this advancement delivers meaningful value across the board.

Read the full article about the self cleaning vacuum furnace