CALL: 1-855-WE-HEAT-IT

Ask the Expert: Solar Atmospheres of Western PA’s Director of Sales Discusses Stress Relieving

1. Can stress relieving help minimize distortion on my parts?

1. Can stress relieving help minimize distortion on my parts?

Yes! As a matter of fact, if you take a cursory read of the machinist’s handbook you will see stress relieving is recommended as a best practice. We commonly see requests for stress relieving on weldments, fabrications, and machined components; but increasingly on additive and printed parts as this technology advances. Stress relieving removes machining stresses, cold working, or in case of AM parts, the unbalanced heat affected areas that can contribute to distortion.

2. Is stress relieving allowed when working to MIL or AMS heat treat specifications?

Yes, in some cases it is mandatory. We work to many MIL, AMS, and BAC specifications on a daily basis. AMS2759, AMS2801, and BAC-5613 represent a large portion of our stress relieving business. Did you know PH grade materials, in the aged condition, can be stress relieved? Per table 1 of AMS2759 / 11 stress relieving must be done 100°F below the aging temperature. Using this method has become popular and necessary to stabilize parts in use or during machining.

3. Are material properties affected during stress relieving?

Trick question! You really must know the scope of work, processes, and needs of your customer. Stress relieving consists of heating the steel to a temperature below the critical range to relieve stress from cold working, shearing, mill / cutting, etc. It is not intended to alter the microstructure or mechanical properties. You would not want to stress relieve a 17-4 stainless steel part at 1250°F if it is going to be aged (H-900) at the final process. However, if you knew it was going to be solution treated and then aged you would be fine. If desired, the material properties of some alloys can be altered by stress relieving; but then, restored with an annealing process or hardening process. Again, consult with your heat treater.

Vacuum Stress Relieving a large aerospace test-stand weldment for aircraft engines

4. What are the negative impacts of stress relieving?

Unintended results or ones that fall short of the goal. Heat treating complex geometries or configurations may require post heat treat straightening or flattening. These post processes must be built-in ahead of time. Predicting results to leave stock on conditions, for instance, can prove challenging. In many cases a trial run, in a smaller furnace, will yield the knowledge needed to ensure the usefulness of stress relieving. If stress relieving does not work, then we will work on plan B, there is always a plan B.

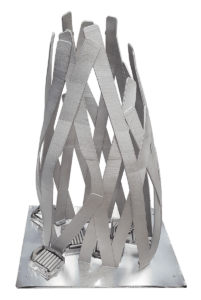

RPM Innovations Inc.’s complex titanium hollow ribbon, additive manufactured part heat treated at Solar Atmospheres (post heat treating)

5. Can finished machined parts be stress relieved?

Absolutely, vacuum stress relieving proves most advantageous! Vacuum stress relieving produces bright, clean finishes in a near net shape. Additionally, stress relieving can, in some cases, correct (straighten or flatten) a warped part post machining or grinding. Influencing the materials at temperature by exercising techniques such as static weight to flatten or utilizing coefficients of thermal expansion (CTE) of dissimilar metals may improve such conditions. Again, it is always best to describe the conditions you are seeing during machining or after a thermal process to see if stress relieving can benefit your production flow. You might walk away saying you wish would have done it sooner.

For more information: https://solaratm.com/vacuum-heat-treating/stress-relieving

And featured in Aerospace Manufacturing & Design Magazine: https://www.aerospacemanufacturinganddesign.com/article/questions-with-michael-johnson/