CALL: 1-855-WE-HEAT-IT

Vacuum Heat Treating

Conserve Electric Power and Save Dollars in Vacuum Processing

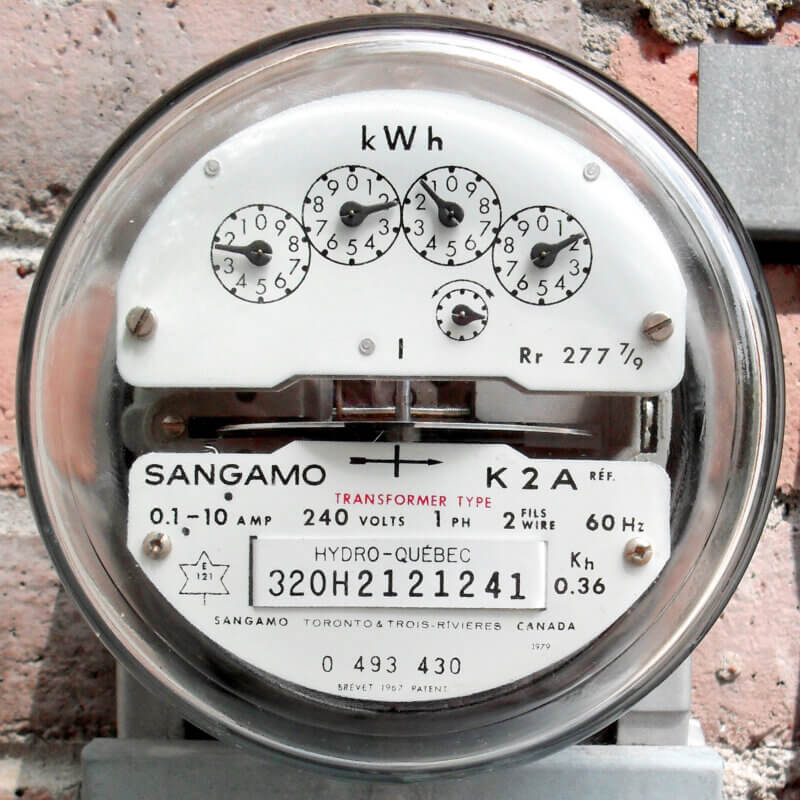

Generally, electric power consumption is insidious because it is not seen and is not considered enough by operating personnel. The following is a summary of power consumed in a typical heat treat plant.

Improving the Safety and Quality of Medical Devices Through Heat-Treating Process Accreditation

Technological change in many industries is often driven by advances in basic science, a move to digital transformation or simply the disruption of the status quo. In manufacturing, the focus on the ability to maintain a process with precision and repeatability based on supply-chain management is also crucial and has led to important advances in industries that make safety and quality imperative.

Preventing Eutectic Reactions and Diffusion Bonding in Vacuum Processing

The purpose of this paper is to explain reactions that can occur during a vacuum processing cycle and different methods of preventing these reactions.

Titanium: A Fascinating History and Future

For all the advances, titanium and its many alloys, has not reached its apex in popularity in the world. Is there any other element that calls to mind the notion of strength quite like titanium?

Vacuum Gas Cooling – Is Pressure or Velocity Most Important? (Part 1)

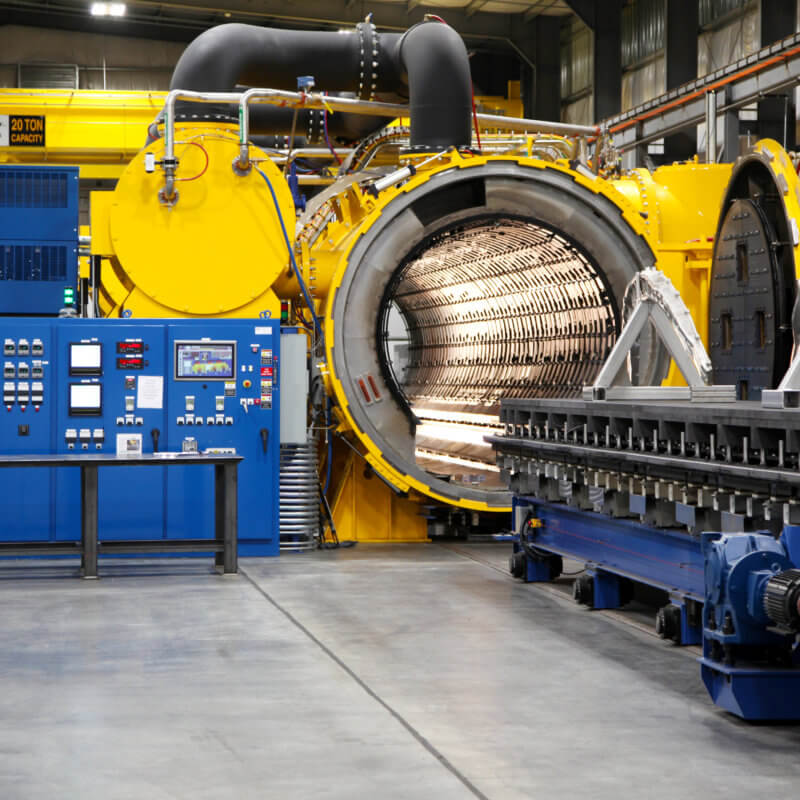

There is an age-old adage that exists in the heat treating world. That supposition states that “the smaller the vacuum furnace, the faster it will quench.” Our study compared the cooling rates of two distinctly sized High Pressure Gas Quenching (HPGQ) vacuum furnaces- a large 10-bar vacuum furnace equipped with a 600 HP blower motor versus a smaller 10-bar vacuum furnace equipped with a 300 HP motor.

The Use of Graphite for Vacuum Furnace Fixturing

The vacuum furnace industry has searched for many years for the ideal material to be used in fixtures and grids for processing workloads at elevated temperatures. The support structures should be lightweight to achieve desired metallurgical results during the cooling phase of the process cycle.

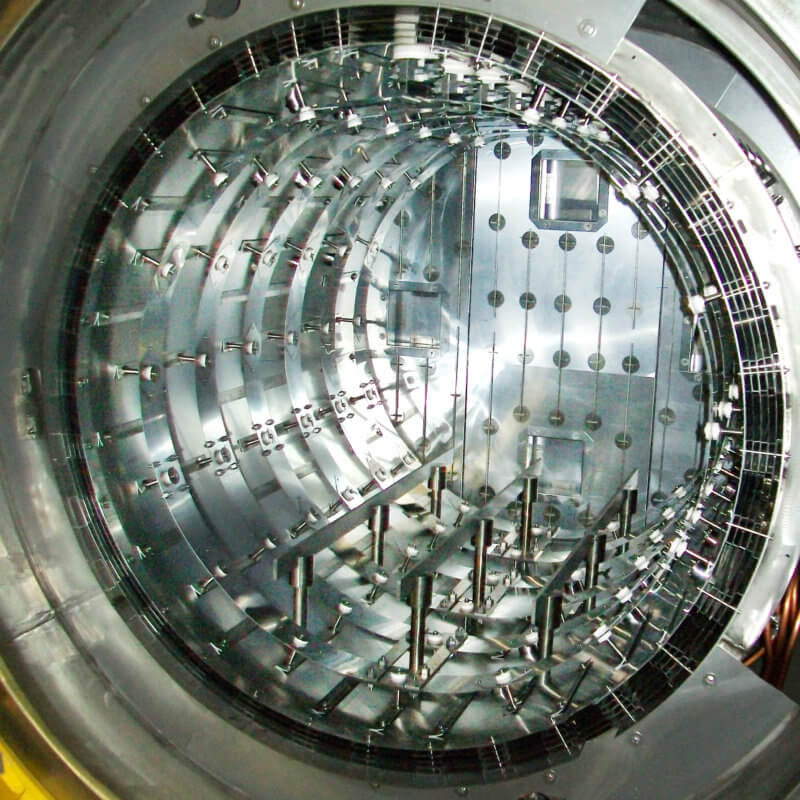

The Returning Need For the All-Metal Vacuum Furnace Hot Zone and Specific Application Advantages

In this article, we will highlight some of the essential design requirements needed to provide the proper all-metal furnace for these critical applications.

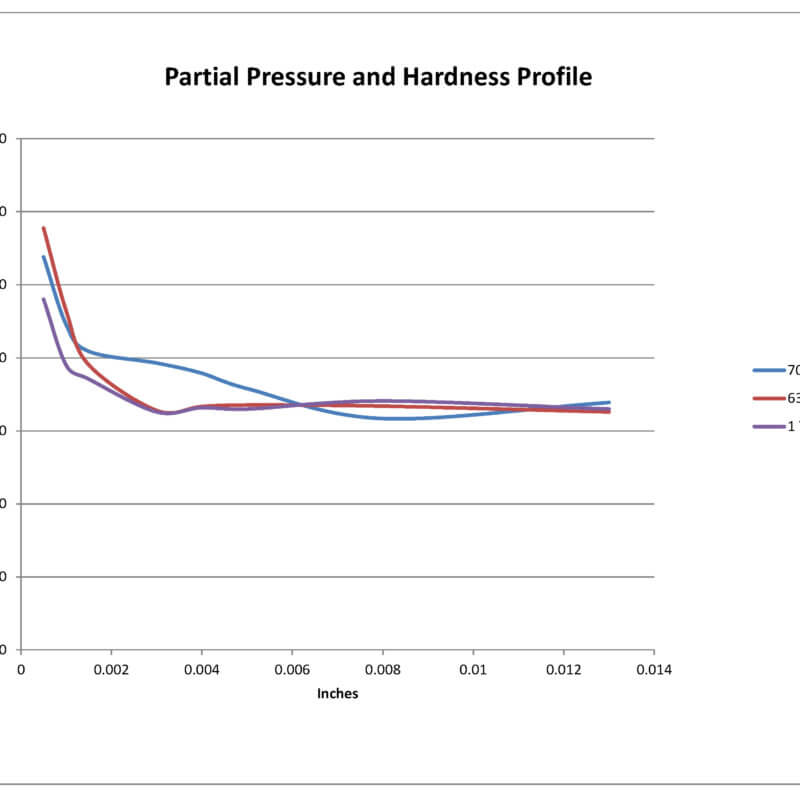

Gas Nitriding of Titanium

This preliminary study revealed that the partial pressure of nitrogen when gas nitriding Ti-6Al-4V in a vacuum furnace can have a significant effect on the nitrided case characteristics.

Dew Point Versus Oxygen Content in Vacuum Processing Part 2

Since the majority of commercial and captive heat treat facilities do not typically operate under controlled environments, the temperature and humidity swings can often be drastic.

Dew Point Versus Oxygen Content In Vacuum Processing

It is well known that accurate measurement of any heat treating atmosphere can have a significant effect on the quality and process yield of heat treated components. Traditionally, dew point analysis has always been the bellwether in determining our heat treating atmospheric conditions.